À propos de LIL

Cement - Extraction, Processing, Manufacturing Britannica

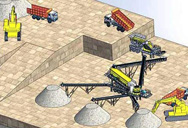

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some

Voir plus

What Are the Parts of a Cement Mills?

2023.8.23 Explore the efficiency and functionality of cement ball mills. Learn how these essential industrial machines grind and blend raw materials to produce high-quality

Voir plus

The cement mill - Understanding Cement

Cement manufacturing -brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the

Voir plus

Cement Mining Process: A Step-by-Step Guide

Calcium, silica, aluminum, iron, and other elements are combined chemically under strict control to create cement. Limestone, shells, chalk, or marl are frequently combined with shale, clay, slate, blast furnace slag, silica

Voir plus

Engineering:Cement mill - HandWiki

2023.11.9 A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that

Voir plus

How Cement Is Made Heidelberg Materials

3 天之前 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared using metering

Voir plus

How Cement Is Made

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled

Voir plus

Cement Production - an overview ScienceDirect Topics

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts

Voir plus

A Contribution towards a More Sustainable

2022.3.5 During the production process of cement, massive CO 2 emissions are released into the environment, while large amounts of raw materials and energy are consumed. In the present study, Portland type

Voir plus

Modeling of energy consumption factors for an industrial cement ...

2022.5.9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's

Voir plus

(PDF) Control System Architecture for a Cement Mill

2015.2.14 The paper presents how a fuzzy controller for a cement mill is designed by defining its structure using Fuzzy Inference System Editor [1]. ... 3 is being constructed by a number of r fuzzy blocks ...

Voir plus

Investigation of Behavior of Masonry Walls

2022.8.31 Mills, C.A. The design of concrete structure to resist explosions and weapon effects. In Proceedings of the 1st International Conference on Concrete for Hazard Protections, Edinburgh, UK, 27–30

Voir plus

Spotlight on the design and construction of silos in the cement

12 July 2022. Silos for Cement and Other Industries. Design and Construction – by BGK Murthy. Material storage silos are complex structures and the internal process dynamics when loading and discharging silos affect the silo structure. Moreover, when they fail, the impact on the cement plant and its staff can be catastrophic.

Voir plus

How many cement plants are producing in the USA 2020?

2020.8.14 Several years before he constructed his first cement plant in 1866, Saylor purchased the land where it and the future mills of the Coplay Cement Company would be located. His first mill, often referred to as plant A, where he made his first portland cement in 1871, was utilized well into the 1890s but was demolished early in the 20th century. ...

Voir plus

how are cement mills constructed - shibang-china

how are cement mills constructed - (USA),INC, Cement Ball Mill/Cement Mill Machinery/Cement Mills-Product . Cement Ball Mill,Cement Mill Machinery,Cement Mills supplied by China . is an exclusively ... Go to Product Center. Meghna Cement Mills Ltd. - Bashundhara Group, PCC are widely used in our country in all sorts of construction.

Voir plus

Cement Silo - an overview ScienceDirect Topics

Ground Improvement for Mitigating Liquefaction-Induced Geotechnical Hazards. Dharma Wijewickreme, Upul D. Atukorala, in Ground Improvement Case Histories, 2015. 1.6.3 Cement silo. The cement silo was constructed immediately south of the B-silos and the new clinker silo (refer to Fig. 1.20).The silo was constructed on a relatively stiff circular raft

Voir plus

Design Considerations for the Construction and Operation of

2014.5.8 Almost all mill towers are rectangular. Concrete mill structures are fairly large and the walls typically need stiffening using vertical wall pilasters (figure 6) that extend the entire height of the structure. Bins are constructed integrally with the outer mill shell, and extend about the upper portion of the tower.

Voir plus

CASE STUDY ILIGAN CEMENT MILLS SILO PROJECT

2021.6.19 ILIGAN CEMENT MILLS SILO PROJECT PHILIPPINES BEC Group of Companies c/o 18 Boon Lay Way #10-159/162 TradeHub 21 Singapore 609966 Tel: +65 6778 6858 Fax: +(65) 6690 9259 Website: be-con Email: sales@be-con Challenges Slip-forming of dual walls concurrently ...

Voir plus

how are cement mills constructed - shibang-china

how are cement mills constructed - (USA),INC, Cement Ball Mill/Cement Mill Machinery/Cement Mills-Product . Cement Ball Mill,Cement Mill Machinery,Cement Mills supplied by China . is an exclusively ... Go to Product Center. Meghna Cement Mills Ltd. - Bashundhara Group, PCC are widely used in our country in all sorts of construction.

Voir plus

how are cement mills constructed - confiterialareal.es

Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, e.g. powder flowability. A typical example is SikaGrind®-400.Cement is so fine that 1 pound of cement contains 150 billion grains.

Voir plus

Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

The vertical roller mill is less power consuming. The energy consumption of a vertical roller mill is around 75% of that of a ball mill of the same capacity. Vertical roller mills can be transported in parts and constructed onsite, avoiding difficult logistical issues and associated costs. The fineness of product cement can be adjusted easily ...

Voir plus

(PDF) Design Considerations for the Construction

2007.1.1 structures are generally constructed from steel and metal panels or from precast concrete. Flour milling is a process that is governed by t he FDA. All construction must be sanitary and

Voir plus

Mortars and masonry—structural lime and gypsum mortars

2021.9.17 Hughes R (1983) Techniques and materials: material and structural behaviour of soil constructed walls. Momentum 26(3):175–188. Google Scholar Jackson MD (2014) Sea-water concretes and their material characteristics. In: Oleson JP (ed) Building for eternity: the history and technology of Roman concrete engineering in the sea.

Voir plus

Ventilation Prediction for an Industrial Cement Raw Ball Mill

2021.6.10 In cement mills, ventilation is a critical key for maintaining temperature and material transportation. ... As a tree-based statistical model, random forest (RF) was constructed and developed by Breiman et al. (1993) . A powerful AI machine learning (ML) model can provide low-bias and low-variation outcomes, with highly accurate predictions

Voir plus

how are cement mills constructed - fonz.co

Cement Rotary Kiln Mill Conveyor Trackback records Zhengzhou Yufeng Heavy Machinery Co.,Ltd, Mining Machinery, Mine Crusher Manufacturer, Continental Conveyor Ltd., etc. Get Price; Sand For Concrete From Steel Mills Induction Furnace Waste . For example Kotdwar a small town of Uttarakhand Steel Mills induction construction on on "Sand For ...

Voir plus

Selection of AC Induction Motors for Cement Plant

2023.11.18 In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications. The criteria for motor selection includes:

Voir plus

What materials are used to make wind turbines?

According to a report from the National Renewable Energy Laboratory (Table 30), depending on make and model wind turbines are predominantly made of steel (66-79% of total turbine mass); fiberglass, resin or plastic (11-16%); iron or cast iron (5-17%); copper (1%); and aluminum (0-2%). Many turbine components are domestically sourced and manufactured

Voir plus

The Decision Algorithm of Cement Mill Operation Index

2023.1.25 Abstract. An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and

Voir plus

how are cement mills constructed - happyplanetplatform

how are cement mills constructed. thyssenkrupp wins major cement plant order in Algeria . 25 Jan 2017 The turnkey cement plant will have a production capacity of 6 000 tons of clinker per day and will be constructed in Sigus in the Wilaya of Oum. The Battle at the Cement Mill and the 2014 IEEE Conference .

Voir plus

Explained: Cement vs. concrete — their

2020.4.3 What makes concrete so strong is the chemical reaction that occurs when cement and water mix — a process known as hydration. “Hydration occurs when cement and water react,” says Ulm. “During

Voir plus

Modeling of energy consumption factors for an

2023.12.4 In the mid-1990s, the vertical roller mill (VRM) was introduced to the cement industry to reduce this energy usage. Besides lowering power consumption, VRMs may improve process capacity

Voir plus

how are cement mills constructed - lamerceria

The new line, which started production in 1968, consisted of extra paste mills, compressors for cement conveying, a further wet-process kiln with diameter of 3.6 meters and length of 150 meters and two 2.6 meter diameter by 13 meter long, 25 tph cement mills. WHITE CEMENT IN CUBA. The use of white cement has a long history in Cuba. OBTENER ...

Voir plus

Selection of AC Induction Motors for Cement Plant

2023.10.6 In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications. The criteria for motor selection includes: operating ...

Voir plus

The development of the flour-milling industry in Spain:

2011.4.1 The first Spanish cement factory was built in Asturias in 1899, with an annual production capacity of 15,000 tons. 37 Thereafter cement was widely used in mortars and concretes as an agglomerant ... The flour mills constructed in Spain between the late 19th and early 20th centuries are an important industrial and archaeological heritage, an ...

Voir plus

How to Dam a River: 9 Steps (with Pictures) - wikiHow

2024.1.3 2. Dig one or more trenches upstream of the dam site to divert the river. Pick a point 10–20 yards (9.1–18.3 m) above the section of river you've selected for your dam. Use a shovel, drainage spade, or trenching hoe to remove the dirt or sand along the riverbank in long, straight pits roughly 1–2 ft (0.30–0.61 m) wide.

Voir plus

how are cement mills constructed - pizzeriacapucine

أحدث المنتجات. crusher for sale south africa coal conveyor system suppliers; energy saving jaw crusher; two stage closed circuit plant; search engines other than google for mining equipment

Voir plus

Cement Mill Report PDF Surveying Beam (Structure)

2019.9.10 These crushed minerals can be easily ground, reduce the energy consumption of the grinding mills, extends the working life of mills and all their components. Fig 1: Cement mill. ANKUSH KESHRIMAL KHANDELWAL/CE/J.K CEMENT LTD. 2 JK CEMENT LTD. 2018-2019. CHAPTER 3 CONSTRUCTION PROCESS. 1. PLANNING 2.

Voir plus

how are cement mills constructed - garazova-vrata-doorhan

how are cement mills constructed : How Are Cement Mills Constructed. 2020-5-30 A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball ...

Voir plus

Cement Mills, Inglewood, Queensland, Australia: 3D Maps

This page provides an overview of 3D Cement Mills maps in the Maphill world atlas. 3D maps show Cement Mills, Inglewood, Queensland, Australia and the surrounding region at elevation angle of 60°. Choose from many map styles. Get free map for your website. Discover the beauty hidden in the maps. Maphill is more than just a map gallery.

Voir plus

Consulter en ligne

- principe broyeur à billes

- moteur moulin à induction

- différence de broyage et de meulage

- pierre crasher la vente en Afrique du Sud

- fer broyeur a disques de minerai

- broyeur de pierresmines de pierres de quartzite

- molino basculante 15 kg de capacidad

- concasseur à cône hydraulique de lallemagne

- Afrique concasseur de granit courir poids par pied cube

- mineral de hierro de peletización en china

- processus de fabrication en pierre utilisé concassage

- où acheter la pierre humide premier rouleau broyeur à Belgique

- imagenes de zarandas vibratorias

- prix d un broyeur à billes

- principe de fonctionnement d' un tamis vibrant