À propos de LIL

Cone Crusher - an overview ScienceDirect Topics

The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These

Voir plus

Analysis of cone crusher performance with changes in

2017.1.1 To gain more effective leverage, crushers for larger particles use steeper cones. Hence the lever at the initial breakage zone is shorter and the machine can apply

Voir plus

Forces in a Cone Crusher Steel in Translation - Springer

2019.3.21 Configuration of basic types of cone crushers: (a, b) for coarse crushing; (c) for medium crushing; (d) for fine crushing; ( 1) immobile cone; ( 2) mobile cone; ( 3 )

Voir plus

A review of modeling and control strategies for cone crushers

2021.8.15 Cone crushers, which are present in secondary or tertiary crushing circuits, usually have minimal control over the feed rate and properties (hardness, moisture

Voir plus

Influence of Two Mass Variables on Inertia Cone

2021.2.4 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

Voir plus

Research on the Wear Behavior of the Fixed Cone Liner of a Cone

The research results show the correctness of using the Yade method to study the wear of the fixed cone liner of a cone crusher, which provides a theoretical basis for reducing the

Voir plus

Evaluation of size reduction process for rock aggregates in cone ...

2020.6.4 Cone crushers noted for their ability to crush hard, abrasive ores, and rocks are of prime importance in the secondary and tertiary stages of crushing operations. The

Voir plus

An Improved Capacity Model of the Cone

2022.2.11 An improved capacity model of the cone crushers based on the motion characteristics of particles considering the influence of the spatial compound motion of the mantle was established by analyzing the

Voir plus

Cone Crushers - SolidsWiki

2022.7.7 Cone Crushers. Principle of a Cone Crusher. Stationary Cone Crusher. A cone crusher is similar in operation to a gyratory crusher, with less steepness in the

Voir plus

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Voir plus

An Improved Capacity Model of the Cone

2022.2.11 The capacity of the cone crushers was investigated theoretically by many scholars. Gauldie [2,3] proposed an empirical model of capacity by analyzing the structure of various crushing equipment.Briggs

Voir plus

(PDF) Cone Crusher Performance - ResearchGate

2015.5.13 Abstract and Figures. PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same ...

Voir plus

A fundamental model of an industrial-scale jaw crusher

2017.5.1 Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

Voir plus

Minerals Free Full-Text Milling Studies in an Impact

2021.3.20 The duration for impact breakage is much shorter than the fragmentation process in the jaw and cone crushers . Whiten [ 11 ] initiated the modelling on which most work on cone crushers is based. Napier-Munn et al. [ 3 ] and Kojovic et al. [ 12 ] extended this approach to vertical impact crushers.

Voir plus

Modeling and Improving the Efficiency of Crushing Equipment

2023.5.16 Over the last few decades, the demand for energy-efficient mineral-processing methods has continued. The necessity to develop energy-efficient technologies for the mineral industry will increase in the future, considering the exhaustion of high-quality resources and severe environmental limitations. The subject of this study is crushing

Voir plus

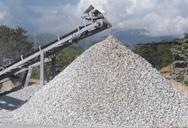

A Detailed Overview of Cone Crushers and What You Need

2020.6.3 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries. Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically.

Voir plus

Forces in a Cone Crusher Steel in Translation - Springer

2019.3.21 The crushing of minerals and ore is of great industrial importance. With global population growth, urbanization, and continuing improvements in living conditions, the productivity and efficiency of existing crushers must be increased to meet the growing demand [].Cone crushers are characterized by a continuous operating cycle and may

Voir plus

Energy Efficiency of a Cone Crusher with Stops Steel in

2023.3.6 The first models of cone crushers were developed in the mid-1920s. Their designs have undergone significant improvements. Some researchers have proposed a series of empirical crusher models based on experimental observation [14–16]. However, until now, engineers have not been able to adapt these models when developing a

Voir plus

Schematic description of the crushing plant, (1) primary

This method simulated the complete crushing process of the cone crusher and realized loop optimization. Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the ...

Voir plus

Minerals Free Full-Text A Dynamic Model of Inertia Cone

2020.9.29 The cone crusher is an indispensable equipment in complex ore mineral processing and a variant of the cone crusher is the inertia cone crusher. A real-time dynamic model based on the multibody dynamic and discrete element method is established to analyze the performance of the inertia cone crusher. This model considers an accurate

Voir plus

Cone crusher modelling and simulation using DEM

2016.1.1 In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and gyratory crushers have previously been the subject for DEM modelling and simulation. Lichter et al. (2009) successfully modelled a laboratory Nordberg B90 cone crusher.

Voir plus

CONE - Chalmers Publication Library (CPL)

2022.11.25 Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same time lowering the production costs. Prediction of crusher performance has been focused on, since crushing is a

Voir plus

Influence of Two Mass Variables on Inertia Cone Crusher

2021.2.7 Minerals 2021, 11, 163 3 of 18 eccentric vibrator (B3); O4 is a planar joint between B3 and B4; O5 is a ball-pin joint between B3 and the connecting shaft (B5); O6 is a universal joint between B5 and the drive shaft (B6); O7 is a revolute joint between B6 and the ground (B0). Figure 1. Schematics of the inertia cone crusher: (a) vertical cross

Voir plus

Diagnostics of cone crusher feed segregation using power

2018.10.1 Moreover, crushing in cone crushers does not occur all at once but in a circular motion. Regarding this intrinsic limitation, the variance in feed across the crushing chamber with respect to mass flow, particle size distribution and other material properties could intensify the potential power draw fluctuations of crusher (Gröndahl et al., 2018).

Voir plus

How to maximize cone crusher performance - Heavy

2021.3.2 Cone crushers are designed for certain reduction ratio limitations. In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs. the size of the crusher discharge) of 4-to-1 up to 6-to-1. "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most ...

Voir plus

Crusher RQHUXVKHU - IOPscience

2022.2.18 crusher, Impact crusher. Cone Crushers are used as secondary crushers in mine or ore processing plants where the process of reduction in size takes place. They follow ‘crush using compression’ mechanism. 2. Literature review Although the study is purely based on the real time phenomena that occurred in the industry in a cone crusher

Voir plus

Nordberg® HP6™ cone crusher - Metso

Known for high capacity, superior end-product quality and energy efficiency, Nordberg® HP6™ cone crusher consumes up to 20% less energy than other cone crushers of the same size. Optimized performance. Nordberg® HP6™ cone crusher features a unique combination of crusher speed, throw, crushing forces and cavity design.

Voir plus

Cone crushers - 英中 – Linguee词典

Cone and thread tubing is 1/8-hard 316 seamless stainless steel tubing that has an undersized outside diameter to assist in coning and threading operations when the tube is used with cone and thread fittings. swagelok.cn. swagelok.cn. 锥形和螺纹卡 套管是 1/8 硬度 316 不锈 钢无缝卡套管,这些卡套管采用略小的 ...

Voir plus

Caring for your cone crusher: A guide to optimising performance

2017.4.7 Cone crushers are versatile machines, but using them as they are set up to function is the best idea. A 4:1 reduction ratio is a standard crusher application. Opting to use it for a 6:1 or 8:1 reduction of material could fall outside the parameters of its intended function, with punitive impact on the machine.

Voir plus

(PDF) ENERGY EFFICIENCY IN COMMINUTION

2020.1.13 New De velopment in Cone Crushers . to Improve Productivit y and Energy Efficiency in C omminution. In Proceedings of SAG . Conference 2015, Vancouver, Canada, 14 pp. Romero-Lage (2012).

Voir plus

The Improved Motion Model of Particles in the Cone Crusher

2021.11.29 The cone crusher is the main equipment in the particle crushing process. The productivity of the cone crusher is determined by the motion characteristics of particles passing through the crushing chamber. In order to accurately describe the motion characteristics of the particles, the influence of the spatial compound motion of the

Voir plus

Minerals Free Full-Text Constant Wear Criterion

2022.6.24 The crushing chamber is the core component of a cone crusher, consisting of mantle and concave parts. Reducing the impact of crushing chamber wear on the performance of cone crushers and the

Voir plus

Research on the Wear Behavior of the Fixed Cone Liner of a Cone

It is estimated that in the past five years, the crushers in the China’s mining industry have consumed more than 2.2 million tons of lining materials. As the main crushing machine of metal ores, a cone crusher is composed of a fixed cone, a moving cone, an upper and lower frame, an eccentric sleeve, a hydraulic cylinder, etc. In the working ...

Voir plus

(PDF) An Improved Capacity Model of the Cone Crushers

2022.2.11 An improved capacity model of the cone crushers based on the motion characteristics of particles considering the influence of the spatial compound motion of the mantle was established by analyzing ...

Voir plus

South Africa Cone Crusher Market Opportunities: Size and

Published Feb 28, 2023. + Follow. TechSci Research has predicted that the South Africa cone crusher market will experience a steady compound annual growth rate (CAGR) during the forecast period of ...

Voir plus

Simulating a laboratory-scale cone crusher in DEM using

2020.7.15 An approach that is far more practical in simulating cone crushers is to use particle replacement schemes, in which particles within a DEM simulation are replaced instantaneously when a fracture criterion is met [15]. Given the convenience and lower computational demand, particle replacement schemes involving spheres have been

Voir plus

Cone crusher modelling and simulation using DEM

2016.1.1 In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and gyratory crushers have previously been the subject for DEM modelling and simulation. Lichter et al. (2009) successfully modelled a laboratory Nordberg B90 cone crusher.

Voir plus

A Dynamic Model of Inertia Cone Crusher Using the

2020.9.29 crushers such as hydraulic cone crushers. The CSS may be manipulated to obtain optimum operating parameters, in general, it is affected by the feed, the eccentric static moment, and the eccentric speed. An inertia cone crusher operation model of the crushing chamber profile was developed by Babaev et al. [4].

Voir plus

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame , and tramp release mechanism (mechanically or hydraulically actuated).

Voir plus

>> Next:La Faon D'appliquer Les Travailleurs Des Utilisés De Logements

Consulter en ligne

- le broyeur à boulets cemtech internationale

- broyeur fin fabricant professionnel de sable

- des caracteristiques de concasseur

- meulage conception de la machine de l expérience

- Afrique concasseur de pierre entreprises rapport annuel

- spécifications dune usine de ciment

- utilisé minerai d or machoire prix de concasseur en inde

- concasseur giratoire de laboratoire

- Broyeur Indonésie Charbon De Cage broyeur

- scories de fer ou de clinker meteorites

- conception de broyeur Indonésie béton

- machines et équipements de la pierre de carrière

- tous les types de risque sur lévaluation des risques concasseurs

- Rouleau de machine à meuler pilée

- Meulage de pierre de plastico resiclad